Licenced Repairers

We are licensed under SGS Baseefa to repair Group I & II hazardous area Motors, along with standard Industrial Motors.

The Process

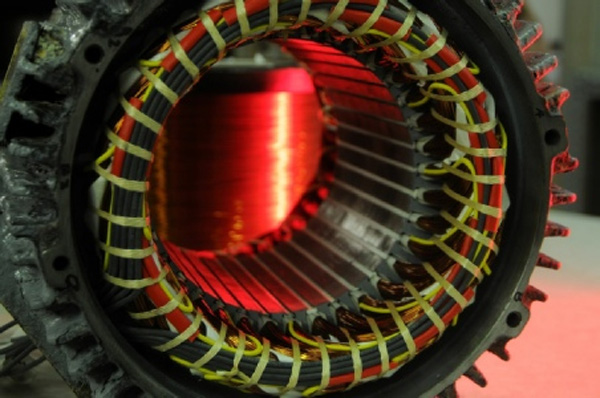

Electric Motors are sent to us with varying amounts of repair work necessary to bring them back to O.E.M. standard.

All Electric Motors undergoing repair are stripped down, cleaned, thoroughly checked, and inspected. It is at this stage that our engineers determine whether or not a new part is to be procured or re conditioned.

Along with the Motor Casing, any part being re conditioned will go into the shot blasting machine, or the glass bead blaster.

New and re conditioned components are re-assembled and painted as required. All bearings, seals and grease nipples are replaced with new. Finally, the Motors are electrically tested, then shrink wrapped ready for dispatch.

We are licensed under SGS Baseefa to repair Group I & II hazardous area Motors, along with standard Industrial Motors.

Our engineers are committed to producing the highest standard of work.